Production of polystyrene blocks

The raw materials of polystyrene are granular granules that are cooked in different sizes in the primary baking machine with steam depending on the density desired. Then, by injecting the water vapor into the seeds and pressing them in large blockers, the granule beads stick together and large polystyrene blocks are formed.

The productive blocks of Yazdasemin Company are in sizes 100 x 100 x 200 cm or 50 x 120 x 400 cm, which is the production of 4 meters long foam that distinguishes the company from other rivals. In addition, the company is able to supply foam depending on the size of the customer.

The other distinguishing feature of the Yazd Steel factory is the precision of its production line for the production of an ultra-precision product. In addition, with complete monitoring of the factory’s quality control unit, the customer’s order is produced at a density difference of 255 ± g.

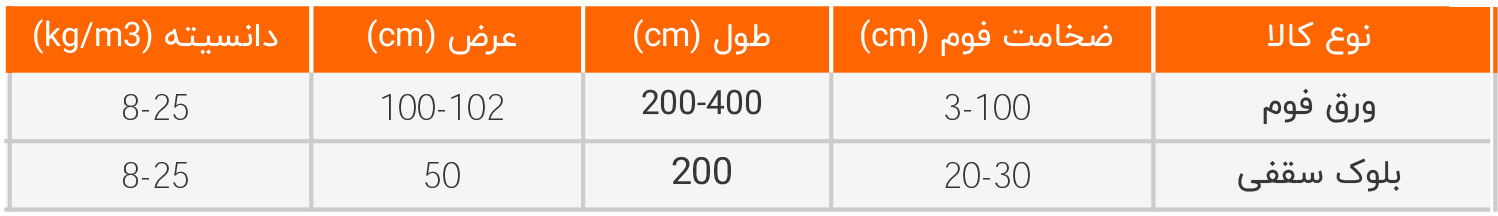

Finally, the polystyrene blocks are cut by cutting machine into two types of roofing blocks and foam sheets, the technical specifications of which are given in the following table.

National Standard of Iran No. 1112 4th year 2834: Fire reaction to materials and construction products Test methods Part Four: The ability to inflate construction products in direct flame contact (single flame source test) National Iranian Standard No. 25905 Year 2831: Building materials Thermal Insulation Products Expanded Polystyrene Products Built-in Factory Features.